Air plasma spray coating

Plasma is considered the fourth stage of matter in physics.

It is a ionised gas made up of charged particles, a wholly neutral set of ions and electrons, whose total electric charge is near zero.

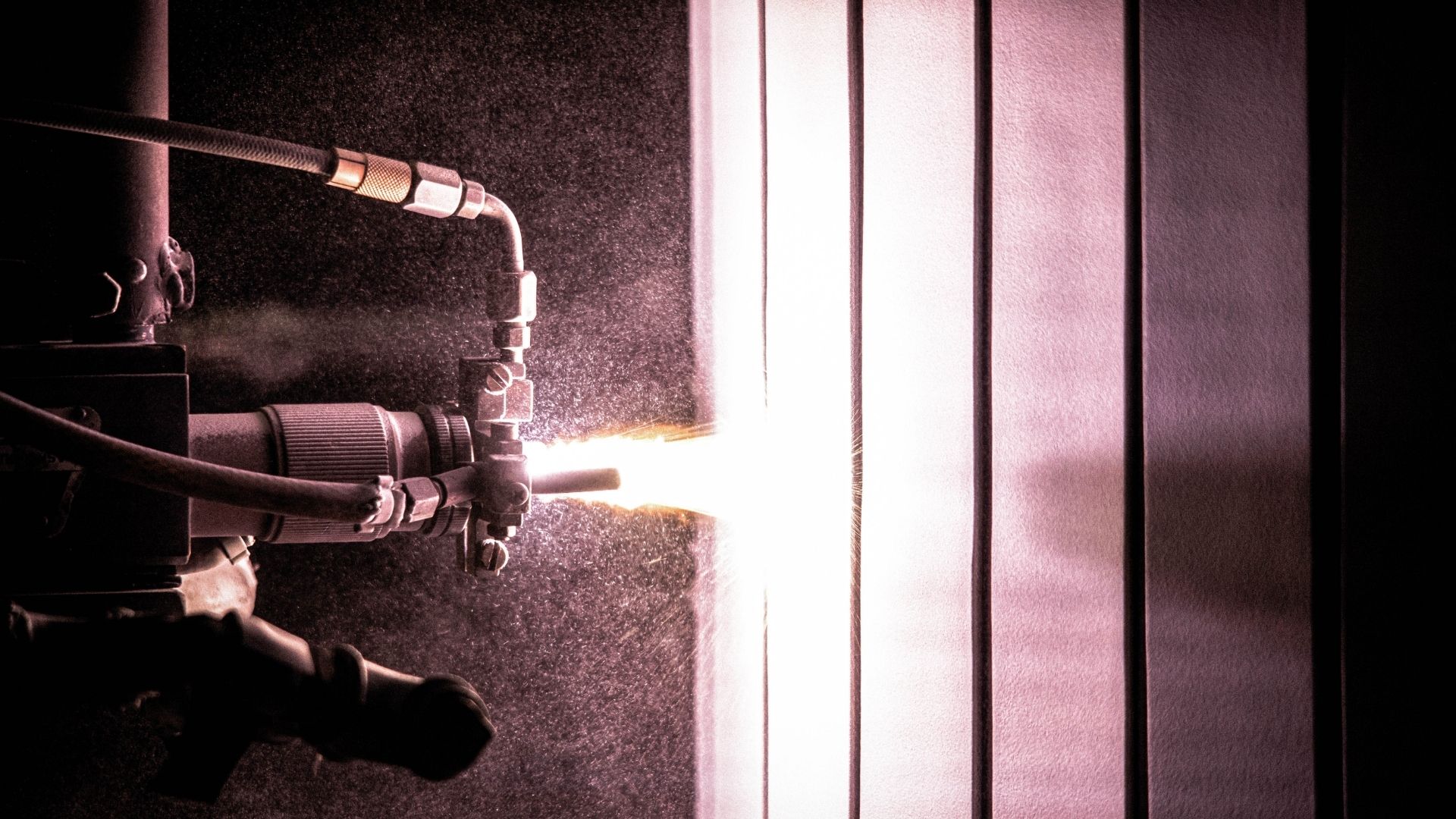

Plasma coating technology employs an electric torch that generates a direct flow of plasma from a nozzle.

Working principle exploits a plasma flame to melt and to accelerate the particles that will form the coating.