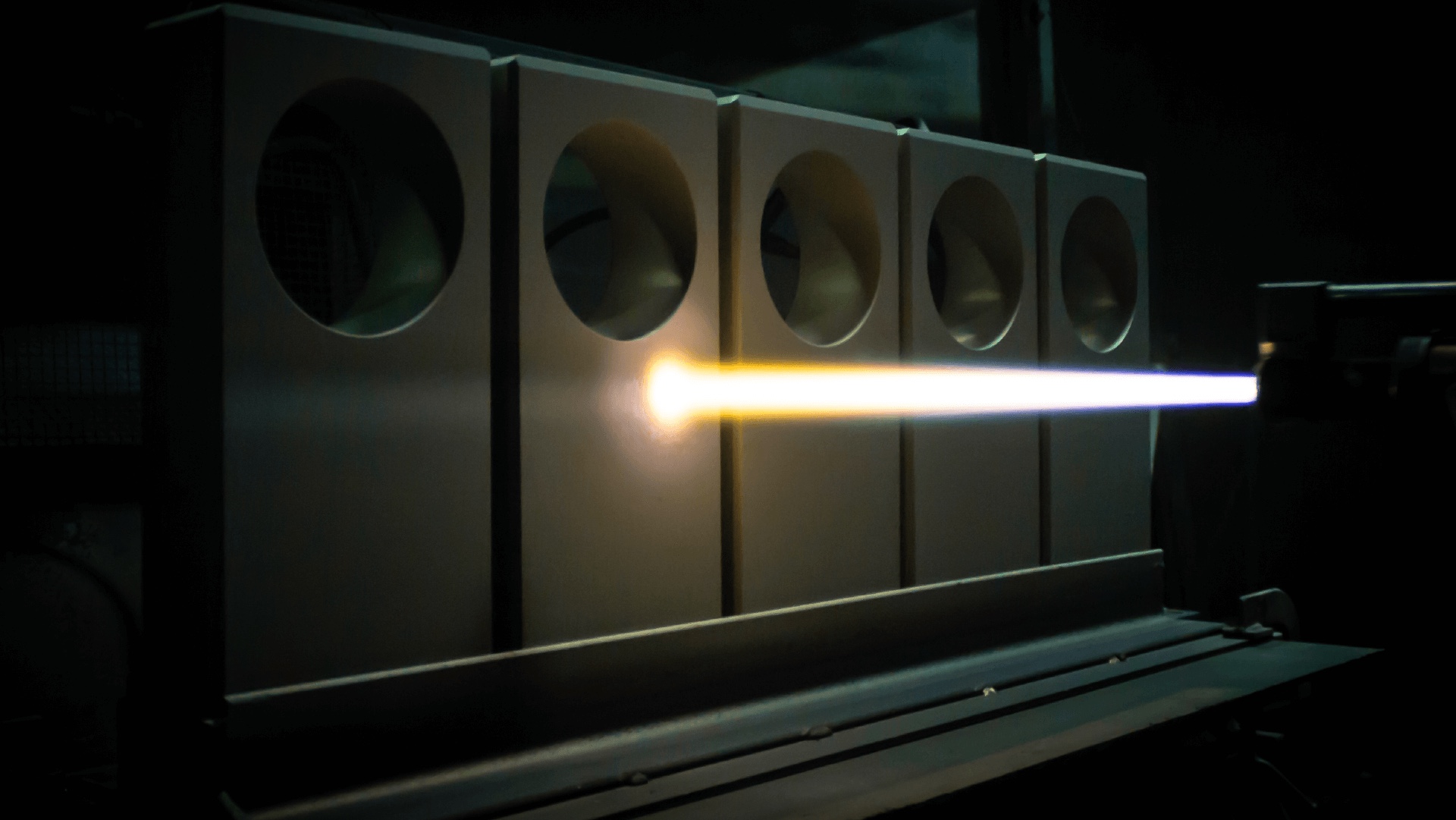

High Velocity Oxygen Fuel HVOF

HVOF thermal spraying process represents an innovative method to apply metallic coatings.

This technology use the kinetic energy generated by the combustion of oxygen and kerosene. High-pressure hot gas flow, created inside a combustion chamber, is conveyed to a converging / diverging nozzle at supersonic speeds. The great energy created in this phase is used to project powder particles on to the surface to be coated. The higher the speed reached by the particles, the better the characteristics of the coating.

Materials coated through HVOF deposition system offer different coating properties based on their chemical-physical nature. Heavier powders, usually made up of carbides and metallic binders, are more suitable for use with the HVOF process. This is because high speeds and low temperatures involved do not cause neither thermal degradation of carbides nor the formation of oxides, since they do not reach their melting temperature. However, we are talking about a versatile process that allows the use of a wide range of filler materials having the most varied characteristics.